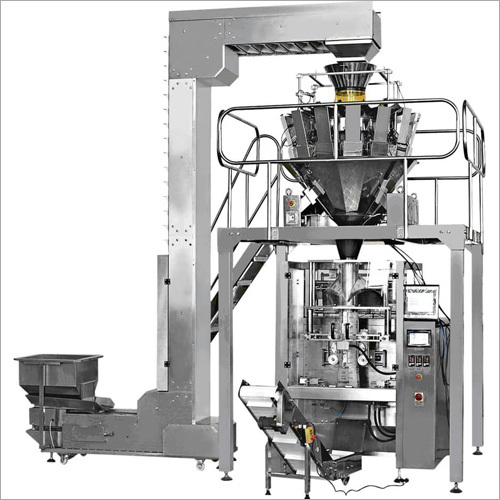

Automatic Weighing Packaging Machine

Price 1000000.0 INR/ Piece

Automatic Weighing Packaging Machine Specification

- Interface

- User-Friendly Control Panel

- IP Rating

- IP54

- Features

- High Accuracy, Fast Packaging Speed, Easy to Operate, Corrosion Resistance

- Usage

- Industrial Packaging

- Power Source

- Electric

- Connectivity Type

- RS232/USB

- Battery Life

- Not Applicable (plugged in)

- Function

- Automatic Weighing and Packaging

- Display Type

- LCD Display

- Application

- Food, Seeds, Granules, Powder, Chemicals

- Size

- 600mm x 700mm x 1650mm

- Automatic Grade

- Fully Automatic

- Product Type

- Automatic Weighing Packaging Machine

- Weighing Scale Type

- Integrated Electronic Weighing System

- Material

- Stainless Steel

- Power Supply

- 220V/50Hz

- Monitor Display

- Digital Touch Screen

- Load

- Up to 50 kg

- Accuracy

- 0.5 g

- Capacity Range

- 10 g 5000 g

- Color

- Silver

- Sealing Type

- Heat Sealing

- Filling Range

- Granule, Powder, Small Parts

- Operating Temperature

- 5C 40C

- Compressed Air Requirement

- 0.4-0.6 MPa

- Hopper Volume

- 25 Liters

- Net Weight

- Approx. 260 kg

- Bag Size Supported

- Length: 50-300mm, Width: 50-200mm

- Packaging Speed

- 15 60 Bags/Min

- Noise Level

- <70 dB

- Film Material

- Laminated Film, PE, PP, Aluminum Foil

- Control System

- PLC Control with Human Machine Interface (HMI)

Automatic Weighing Packaging Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 15 Days

About Automatic Weighing Packaging Machine

This Automatic Weighing Packaging Machine is rigidly constructed by our skilled professionals using high-quality raw materials and advanced technology so as to cater the variegated demands of the clients at affordable rates. This machine is used to pack the food, medicine, and other products for selling and shipping purposes. Its high strength, long service life, immaculate finish, rugged construction, stainless steel body and operational ease makes it highly acclaimed in the marketplace. This Automatic Weighing Packaging Machine is available in different sizes and configurations as per the industrial norms.

Precision and Speed for Diverse Needs

Offering a rapid packaging speed of 15 to 60 bags per minute and an accuracy of 0.5g, this machine caters to a wide range of industries including food, seeds, and chemicals. With the integrated electronic weighing system, users can package a variety of materialsgranules, powder, or small partswith consistent results. The large 25L hopper ensures extended operation, minimizing refills.

User-Friendly Technology and Control

Equipped with PLC control, a human-machine interface (HMI), and a digital LCD touch screen, operators can monitor and adjust settings effortlessly. The RS232/USB connectivity and ergonomic control panel provide enhanced operational convenience, enabling easy integration and minimal training for users.

Built for Durability and Safety

Made from stainless steel and rated IP54, the machine offers excellent corrosion resistance and protection against dust and water ingress. With a low noise level below 70dB and operating temperature range of 5C to 40C, it maintains a safe and comfortable work environment, making it ideal for continuous industrial use.

FAQs of Automatic Weighing Packaging Machine:

Q: How does the automatic weighing and packaging process work in this machine?

A: The machine uses an integrated electronic weighing system to accurately measure the product from the 25-liter hopper. Once the preset weight is reached (between 10g and 5000g), the machine automatically dispenses the product into a bag, seals it using heat sealing technology, and completes the processall managed by a PLC control system with HMI.Q: What types of products can be packaged using this machine?

A: This machine is suitable for packaging granules, powders, and small parts. Its versatile enough for industries dealing with food, seeds, chemicals, and other granular or powdered materials, thanks to its wide filling and bag size range.Q: When is this machine most beneficial for industrial applications?

A: The machine is ideal for industrial settings requiring precise, high-speed, and consistent packagingsuch as production lines in food processing, seed sorting, chemical granule packing, or similar applications that demand productivity and accuracy.Q: Where should this machine be installed for optimal operation?

A: Install the machine in a clean, dry, and leveled industrial workspace with an ambient temperature between 5C and 40C. Ensure access to a stable 220V/50Hz power source and compressed air at 0.4-0.6 MPa, as per the machines specifications.Q: What maintenance is required for this packaging machine?

A: Regular cleaning of the stainless-steel surfaces, hopper, and sealing jaws will ensure hygiene and efficiency. Periodically inspect weighing sensors, seals, and electronic interfaces, and check for any wear and tear. Always follow the manufacturers maintenance guidelines for optimal performance.Q: How does the machine ensure operational accuracy and user safety?

A: Accuracy is maintained through the integrated electronic weighing system offering 0.5g precision, with the PLC and digital touch screen allowing real-time monitoring. The machine operates below 70dB and boasts an IP54 rating, safeguarding users with its low noise and enhanced protection against dust and water.Q: What are the primary benefits of using this fully automatic packaging machine?

A: Key benefits include rapid packaging speeds, high weighing accuracy, corrosion-resistant stainless steel construction, and ease of operation via user-friendly controls. These features minimize labor requirements, increase output, and ensure hygienic, consistent packaging results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weighing Packaging Machine Category

2 Head Linear Weighing Packing Machine

Price 150000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : 220V / 50Hz

Weighing Scale Type : Other, Linear Weigher

Display Type : LCD Touch Panel

Accuracy : 0.5 2g

4 Head Linear Weighing Packaging Machine

Price 550000 INR / Piece

Minimum Order Quantity : 1 Piece

Power Supply : AC 220V, 50/60 Hz

Weighing Scale Type : Other, Electronic Linear Weigher

Display Type : Digital

Accuracy : 0.21g

Automatic Multihead Weighing Packaging Machine

Price 1000000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS